Latest Posts

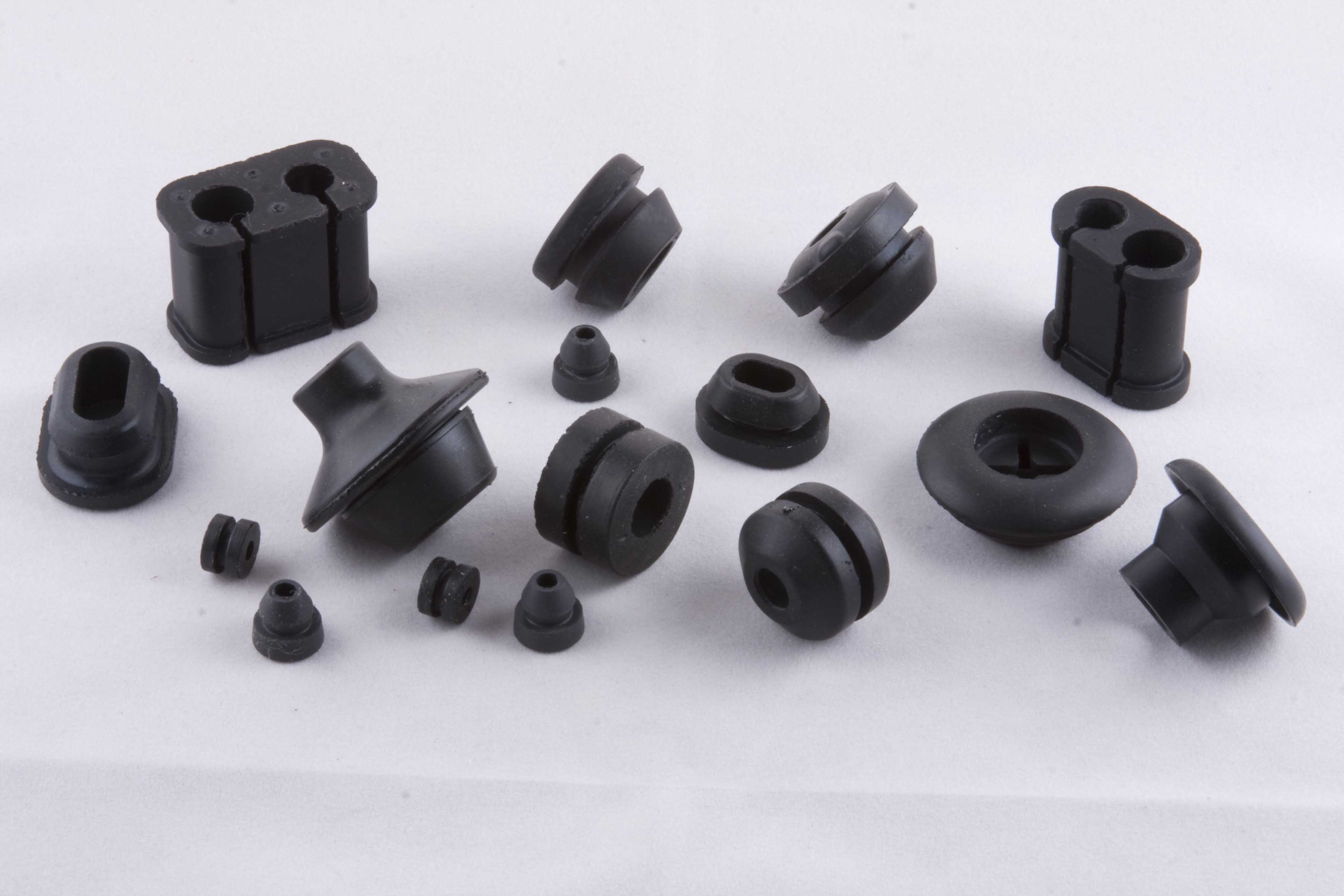

6 Common Uses of Industrial Rubber Products

Rubber is a versatile material with multiple industrial applications. Industrial rubber products are in high demand because of their…

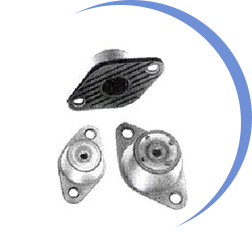

Design Considerations for Manufacturers While Producing Engine Mounts

Engine mounts are crucial components in different motor-operated units. From vehicles…

How Do Rubber Expansion Joints Facilitate Seamless Pipeline Functionality?

Rubber expansion joints play a significant role in ensuring the efficient operation of pipeline systems across diverse industries. They…

Why Should Manufacturers Invest in Industrial Rubber Products?

If you manage an industrial business, you should manage product values to maintain high-quality rubber. The expert manufacturer of…

Different Usages of Rubber Expansion Joints

Rubber expansion joints are installed in gas and air to power gas turbines, power plants, chemical plants, and diesel…

Steps To Pick The Best Manufacturer for Industrial Rubber Products

Industrial rubber products…

How Do Industrial Mountings Improve Equipment Stability and Longevity?

Industrial mountings are components used to support machinery, minimise vibrations, and ensure stability. Their function is to protect the…

The Importance of Choosing the Best Manufacturer for Industrial Rubber Hose

In the current industrial landscape in India, the seamless flow of gas, fluids, and materials is crucial for a…

Role Of Rubber Expansion Joints to Ensure A Smooth Pipeline Connectivity

The rubber expansion joints, also called rubber bellows, are vital components in maintaining the functionality of pipelines in different…